These virtual replicas of physical objects and systems play a key role in industry. Performance improvements, process optimisation and cost reductions are some of the many benefits they bring. We look at an example from the pharmaceutical industry with Actemium.

In architecture, construction, health, urban development, commerce, and of course, industry – digital twins are being rolled out across all sectors. As Frank Berger, Digital Business Development Manager at Actemium Germany, says: “From design optimisation and product innovation to predictive maintenance and reduced stoppages, along with greater operational efficiency, improved decision-making and reduced costs, digital twins offer so many advantages.”

However, the barriers to developing this technology (a lack of technical expertise, the costs, cybersecurity issues, cultural resistance, regulatory compliance, and so on) are many and varied. Nevertheless, the success of organisations such as the VINCI Energies Digitalschmiede in Frankfurt, where numerous digital twin pilot projects have been developed, is testament to the widespread interest in these digital models.

“VINCI Energies collaborates with various stakeholders to stimulate digital innovation. Initiatives such as our Gallery Walks [virtual visits] are introducing people to real-world examples in contexts such as industry, cities and energy,” says Frank Berger. “Actemium is already using advanced technologies such as mobile scanners, drones and 3D CAD software to create digital twins. These technologies enable us to precisely capture and represent physical assets, processes and environments.”

3D simulations

Pilot projects and use cases are abundant. Amecha, a VINCI Energies subsidiary in the Netherlands designs, builds and optimises machines and equipment for the manufacturing industry, with a particular interest in developing mechatronic solutions. It has been collaborating since 2023 with XR 4 Industry, a company specialising in the development of simulations for virtual validation and commissioning of machines, production lines and robotic solutions.

“The adoption of digital twins is essential for the successful completion of projects to deadline”

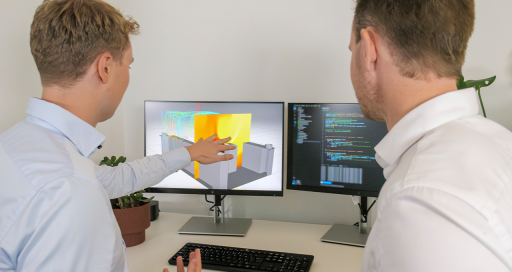

Since beginning 2023 the two firms have been working together on the development of digital twin creation software. “Two of our people have been trained to use XR 4 Industry’s in-house software to create 3D simulations or digital twins of machines still in development,” explains Rik Derkx, Engineering Manager at Amecha. “The objective is to validate designs in progress, to reduce unforeseen production problems and to shorten the time-to-commissioning.”

One of the pilot projects, currently in the development phase, has already shown its functionality by connecting a digital control system to a digital twin in order to test the software. “We now just need to integrate the Digital Twin technology with our own engineering process so our customers can benefit,” concludes Rik Derkx.

Unique technical challenges

In Germany, Actemium has already moved into the application phase. The VINCI Energies industry brand used digital twin technology to support one of its customers in the pharmaceutical sector. “3D digitisation was instrumental at every stage of the construction process,” says Michael Elstner, Mechanical Site Manager at Actemium Controlmatic West in Germany.

The project in question involved the digitisation of a 180-metre-long pipeline bridge. “This type of complex structure presents unique technical challenges, particularly when it is necessary to incorporate new elements such as a pipeline or expansion joints,” explains Michael Elstner. “In this specific case, there were three critical points where the new pipeline had to be connected. Another major challenge was the digitisation of the upper section of the bridge, which was 10 metres up, meaning we had to use a cherry picker to reach the more awkward areas.”

By scanning the entire site and creating a digital twin, Actemium was able to generate detailed measurements, which provided the basis for all the project planning. “With this data, we were able to considerably reduce the risk of errors and ensure that all the different parts would fit perfectly into the existing structure,” says Michael Elstner. “Thanks to this digital process, we were able to take measurements with unparalleled precision, for a time saving of 50% compared with conventional methods.”

Real-time tracking

With construction under way, the 3D digital model continued to play an essential role. The digital twin made it possible to track project progress in real time, comparing each stage with the forecast and identifying any discrepancies. “This made project management far easier, improved our overview of milestones and ensured the schedule was adhered to,” says Michael Elstner. Digitalisation also facilitated the creation of detailed documentation to aid communication with stakeholders and the management of unforeseen events. Ultimately, “The data collected, at a resolution of 5 mm, provided a sound basis for subsequent works, ensuring perfect consistency.”

For Michael Elstner, in a sector such as the pharmaceutical industry, where “The slightest error can have major consequences, the adoption of digital twins is essential for the successful completion of projects to deadline.”

10/15/2025