The world’s largest telescope is under preparation in Poitiers with support from Actemium

Reading time: 4 min

The European project the Extremely Large Telescope will be operational in Chile from 2027. The operation to polish its oversized mirror is now under way, primarily in France. Actemium Maintenance Ouest Centre is working on this specialised task on behalf of Safran.

The larger the main mirror, the greater its resolving power. The ELT’s mirror is an unprecedented 39 metres in diameter.

This will be the largest telescope in the world. With a volume around eight times that of the Arc de Triomphe, it will above all boast unprecedented resolution. Because the ELT (Extremely Large Telescope) needs to see very far indeed, to observe clusters of stars far beyond our galaxy, to probe the birth of planetary systems and help us understand how the universe was formed.

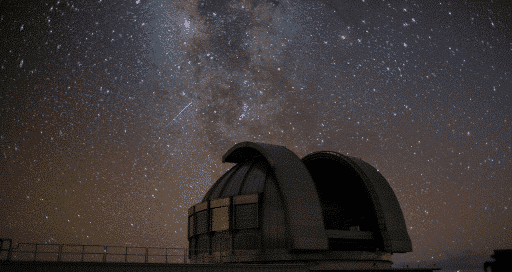

This technological feat will be accomplished from northern Chile, and specifically the Cerro Amazones, a mountain rising 3,000 metres above the Atacama Desert. The environment there offers extraordinary conditions for observation: almost 330 clear nights a year, high air stability and a perfectly dry atmosphere transparent to infrared radiation.

The telescope’s main mirror is composed of 798 hexagonal mirrors, each measuring 1.40 m.

The ELT’s power is equivalent to that of the world’s 16 largest currently operating telescopes combined. Its secret – the primary mirror. The larger the light-collecting surface of this mirror, the greater its resolving power. The main mirror of the ELT is a never-before-seen 39 metres in diameter. By way of illustration, the fault tolerance for each hexagonal segment is not to exceed 10 nanometres, which is equivalent to the presence of a single ladybird on the entire land area of France.

A race for power – and against time

Behind this project is the European Southern Observatory (ESO), an intergovernmental organisation of 16 leading countries in the field of astronomy. For Europe, the issue is at least as much political as scientific. Several other projects to install ultra massive telescopes began simultaneously around the world, including the Thirty Meter Telescope (30 m in diameter) and the Giant Magellan Telescope (25.4 m), both American undertakings.

A race for power, then. But also a race against time. While the TMT is not scheduled for delivery in Hawaii until 2030, the ELT should be operational from 2027. For the companies involved in this European project worth €1.3 billion, the ability to meet deadlines presumably features prominently in the technical brief.

As a specialist in optronics, avionics and electronic guidance systems, Safran Electronics & Defense has been tasked with polishing and installing the mirrors. The telescope’s main mirror is actually composed of 798 hexagonal mirrors, each measuring 1.40 m, plus 133 spare mirrors. Safran will therefore need to polish 931 mirrors. The operation began in 2020 in a specially constructed building in Sain Benoît, near Poitiers.

20 machines in use

The telescope’s accuracy depends on the crucial and painstaking polishing operation. The process involves a series of extremely technologically advanced stages, from pre-polishing to cleaning, via lapping, smoothing and ion milling. These are performed by a total of 20 machines, operating either through robotics or digital control.

Actemium Maintenance Ouest Centre, a VINCI Energies business unit specialised in industrial maintenance, is tasked with the preventive and corrective maintenance of the polishing equipment across the entire production chain. “Each part manipulated by these machines costs several hundred thousand euros”, says Maël Lafaurie, a project manager at Actemium Maintenance Ouest Centre, “Meaning that even the slightest fault is completely unacceptable”.

To convince Safran, the business unit created a turnkey solution that combines process digitalisation, a maintenance plan, a range of service packages, a defined spare parts inventory and operational maintenance. All this is to be done while dealing with the constraints that production rates place on equipment installation, commissioning and availability. “We also perform numerous weather checks and ourselves maintain the inspection equipment”, adds Baptiste Champalou, who supervises the three Actemium technicians assigned full-time to the Saint Benoît site. The contract started in September 2019 and is due to conclude in 2024.

15/02/2023