Additive manufacturing, a key technology of the industry of the future, is shaping up as a way to meet industrial goals by producing more, better, and at lower cost.

Because additive manufacturing shares features – autonomy, flexibility, intelligence, and adaptability – with the industry of the future, it can be considered a key factor in industrial transformation and acceleration.

“It is a fairly revolutionary procedure,” says Alexandre Mandon, pre-sales engineer at Actemium Saint-Etienne Process Solutions (VINCI Energies). “So far, parts – especially machine parts – have mainly been manufactured by subtractive processes, in which material is removed to form the final part,” he explains. “Additive manufacturing takes the opposite approach, adding layers of material to obtain the final product, for example via polymerisation in the case of plastic, fusion in the case of metal, and so on.”

Additive manufacturing opens up new possibilities. “It can be used to make parts with complex geometry that are virtually impossible to produce with conventional processes, such as multidirectional and multichannel components, and lattice structures,” says Alexandre Mandon.

Additive manufacturing accelerates innovation by reducing the time it takes to move from design to production.

Additive manufacturing can, for example, be applied in the major aerospace sector. “The most advantageous aspect in the aerospace sector is the fact that topological optimisation can substantially reduce part weight,” says the Actemium expert. The weight of a titanium aluminide turbine blade can be reduced by 50% – a move that is clearly beneficial in the aerospace industry, since lower part weight means reduced fuel consumption.

The technology also accelerates innovation by reducing the time it takes to move from design to production. “A 3D model of the part is created via this technology. The manufacturing process can then be initiated immediately to obtain the final product” within one week instead of the eight weeks it takes to produce the same part via conventional casting, says Alexandre Mandon. “Additive manufacturing is therefore widely used in prototyping to validate products and components.”

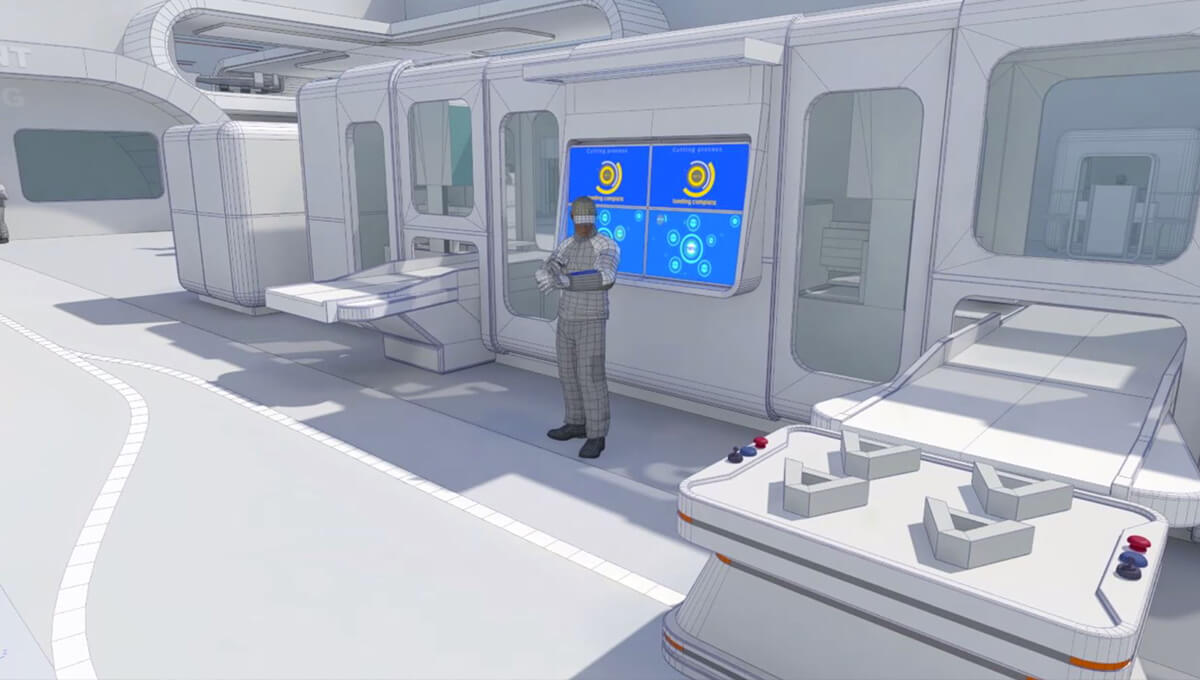

To take advantage of these features, five Actemium business units have joined forces within the “Tech Team” working group to set up the ALAFU (Atelier LAser du FUtur – laser of the future workshop) project. “We designed and modelled a turnkey solution based on ACTEMIUM’s complementary solutions, and more specifically, centralised remote supervision, powder process equipment, automation, and robotisation of transfer and post-processing operations such as heat treatment, finishing, and non-destructive testing. The ultimate goal of the comprehensive additive metal manufacturing workshop is mass production,” says Alexandre Mandon.

Parts of the workshop have already been used in other projects carried out by the Actemium network, but what is new here is the fact that it covers the value chain as a whole, from supply of the powder to packaging of the parts. ALAFU thus addresses several industrial issues, such as the cost of parts.

“Additive manufacturing, especially the metal powder bed process, is very costly as things now stand, because some materials are very expensive. ALAFU brings our powder recycling expertise into the equation,” says Alexandre Mandon. In addition, ALAFU automates and secures the process to make production more reliable and reduce costs, thus supporting mass production. The next step for ALAFU, in the run-up to a demonstrator, is immersion in the workshop via a virtual reality mask.

Find out more:

09/06/2017